| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : Longxingsheng

Model Number : LS-900B

Certification : CE/ISO-9001

Place of Origin : China

MOQ : 1

Supply Ability : 5 Sets per month

Delivery Time : 7-30 workdays

Packaging Details : L/C, D/A, D/P, T/T, Western Union, MoneyGram

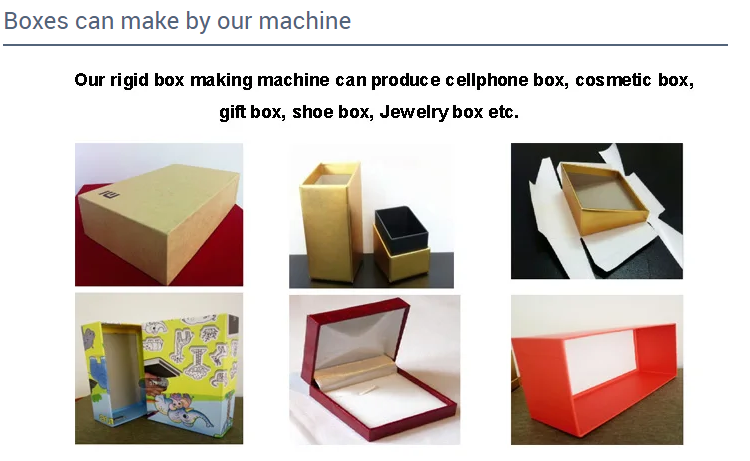

Product name : Bi-Channel Intelligent Fully Automatic Rigid Box Making Machine For Wine Luxury Bottle Cuo Box

Box size(max) : L400*W300*H100mm

Box size(min) : L80*W60*H15mm

Paper size(max) : L550*W450mm

Paper size(min) : L130xW120mm

Max cardboard size : L580xW380mm

Min cardboard size : L110xW90mm

Air pressure : 40L/min

Machine dimension : L6600xW6250xH2800mm

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | L580xW380mm |

| Min cardboard size | L110xW90mm |

| Box size(Length) | L80-400mm |

| Box size(Width) | W60-300mm |

| Box size(Height) | H15-100mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-3mm |

| Edge folding size | 10-90mm |

| Turn in depth | 15-80mm |

| Motor power | 25kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 40L/min |

| Machine dimension | L6600xW6250xH2800mm |

| Weight of machine | 6600kg |

1. Paper loading section: dual paper feeding platform, independently controlled

2. Feeding system: The feeder automatically circulates and feeds the material.

3. Belt adjustment system: non-stop belt adjustment

4. Adhesive coating system:: Features an integrated adhesive coating, easy to clean, and leak-proof system.

5. Paper feeding section: Paper is fed by a servo-driven cam, effectively preventing double feeding.

6. Computer control: servo control digital quick size adjustment

7. Forming system: No need to replace the folding knife and air pressure plate.

8. Cabinet positioning system: large size range positioning, wide range of applications, can operate in single mode.

9. Box retainer: The box retainer can be raised and lowered without damaging the bottom of the box.

Press again and the bottom of the box will stick firmly.

Black and white tape allows for more color applications

Robot arm: high precision ±0.1mm

It uses dual cameras to work independently to take quick and clear photos.

1. Professional QC and QA team to ensure all products are qualified before shipment.

2. Transportation method: sea transportation

3. Warranty period: 1 year, damaged accessories will be replaced free of charge during the warranty period

4. Install the machine: We will arrange engineers to go to the customer's factory to install the automatic machine

5. Machine use: We will send instructions or videos

6. Machine inspection: We have a professional after-sales team to connect with customers to check problems with the machine. If necessary, we will arrange for engineers to inspect the machine remotely to find out the cause and solve it.

7. Contact person: Lyla: 0086-13829162915 Cora: 0086- 13826942085 Mia: 0086-13686086436

FAQ

INSTALLATION SERVICES

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and

preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

|

|

Fully Automatic Double Positioning Double Molding Rigid Box Positioning Machine Images |